Why do ERP implementations fail?

More often than not, the reasons for ERP implementation failures come down to poor planning, lack of funding, unrealistic expectations, and insufficient training and support.

ERP implementations often get a bad rep due to a handful of disastrous and publicised ERP implementation failures. These often circulate in headlines for weeks and can result in court cases, lost market credibility, and a stock price taking a nose dive.

Thankfully, all ERP implementations don’t have to end in chaos. By researching the main causes of some well-documented ERP implementation fails, you can avoid making them yourself.

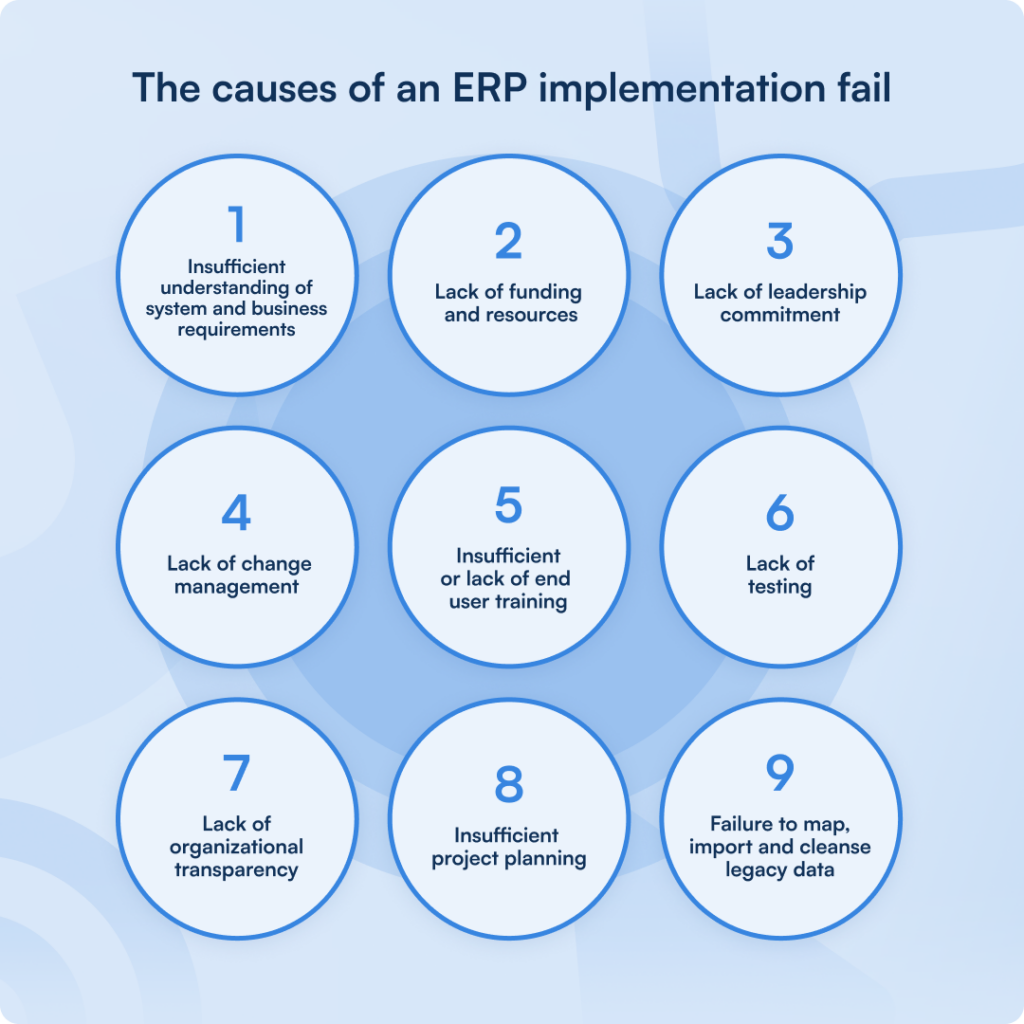

The causes of an ERP implementation failure

While each organization and their ERP software is unique, there are some common causes that cause ERP implementation fails, including:

- Insufficient understanding of system and business requirements

- Lack of funding and resources

- Lack of leadership commitment

- Lack of change management

- Insufficient or lack of end user training

- Lack of testing

- Lack of organizational transparency

- Insufficient project planning

- Failure to map, import and cleanse legacy data

The more complex the ERP implementation process, the more likely it is that there are multiple reasons for the project failure.

Insufficient understanding of system requirements

How many organizations have spent millions of dollars on new systems, only to realize that the software doesn’t actually help with streamlining operational processes?

Not understanding or fully mapping out what processes the new ERP should solve can result in a failed attempt at an ERP implementation. The core team members should all be involved in the decision-making and initial planning process.

Lack of funding and resources

Unfortunately, ERP systems often rack up costs, both before and after successful implementation.

It’s not uncommon for overly optimistic financial forecasts, and more often than not, the budget overruns. Look for a solution that works within your designated budget, but also account for potential ongoing support after the impelementation.

Lack of leadership commitment

Internal resistance should be a tell-tale sign for a failed ERP implementation.

While it is possible to successfully launch a new software without committed leadership, you risk not reaping all the benefits from your digital transformation. End users can remain unmotivated and discouraged to switch to the new software.

Lack of change management

Often, big project costs associated with big software rollouts can be mitigated by ignoring the importance of effective change management.

At its best, properly organized change management helps ensure that all intended results and outcomes are reached by supporting individual transitions. This means that, for a successful ERP implementation, all employees meant to use the new software are able to adopt and use it in their daily lives.

ERP systems don’t automatically solve all problems within the manufacturing cycle or other operations. The effectiveness of an ERP system is directly derivative to how well the end users know how to use the software to automate routine tasks.

If the end users of the new software aren’t adequately trained, you risk decreasing the productivity of your employees, alongside data accuracy. Chances are that an unfamiliar software that users find hard to use discourages and demotivates the workforce further.

Lack of testing

Disregarding or rushing the testing phase of software implementation can have huge consequences.

Lack of testing can cause internal chaos post-launch, especially if you encounter supply chain-related problems, like issues with contractor invoicing or lack of oversight of financial data.

Lack of organizational transparency

There are two critical mistakes that a team can make during any software rollout process.

Firstly, the implementation team should clearly communicate the goals and timelines of the project internally, so that each department knows when to expect to switch to the new ERP.

Secondly, the team should keep open and transparent log of the whole process from start to finish. This means having internally available meeting notes, project updates, and other important information readily available. This helps to get others up to speed in case there are any changes within the core team at any point during the project.

Insufficient project planning

Like with any project, well planned is half done.

Rushing the initial planning phase can result in overlooking or missing important aspects of the ERP implementation as a whole. By not mapping out which departments need access to the new software, you could cause a lot of problems post-launch.

For instance, you could be dealing with wrong people having access to the wrong things, end users not knowing how to best use the software to automate routine tasks, or making decisions based on inaccurate or downright faulty data.

Failure to map, import and cleanse legacy data

It’s quite rare for an organization to not have existing data when an ERP implementation is considered.

In order to reap the proper benefits and get a return on the initial software investment, it’s important to understand the types of data that already exists, and how it’s been categorized and managed historically.

If legacy data isn’t considered during the ERP implementation process, you risk having skewed data in your new system, and lacking historical insights on things like purchasing trends or past sales figures.

Top 6 ERP implementation failures

The bigger the organization, the more variables are at play when it comes to any software rollout. Regardless of the size of your company, learning from others’ mistakes can help you prepare better for an ERP implementation at your organization.

Case study: Target Canada

Main issue: Insufficient end-user training

When Target expanded to the Canadian market in 2013, the team was optimistic about avoiding the typical ERP failures. After all, they had a new system in place and no legacy data to cleanse and convert.

Unfortunately, due to lack of end user training, data input was done wrong by inexperienced employees. With thousands of incorrect manual entries, the company’s supply chain quickly collapsed.

It’s easy to assume that by simply having a new ERP system will fix all existing processes. The truth is that unless you allocate resources towards employee training, it won’t matter how good your ERP features are. If end users input wrong data and make serious mistakes in configuring the software, you’re unlikely to see the benefits of your ERP solution.

Case study: Waste Management

Main issue: Insufficient project planning and implementation

Sometimes, an ERP implementation fail can result in a more public spat between the ERP vendors and their clients.

In 2008, trash-disposal company Waste Management sued SAP, an ERP vendor, for $100 million claiming the ERP software to be “undeveloped, untested and defective” for the US market.

What was originally meant to be an 18-month long ERP rollout ended up lasting several years and costing Waste Management $350 million in lost sales on top of the initial implementation cost of $100 million.

Case study: National Grid

Main issue: Insufficient project planning and inadequate testing

Any complex ERP implementation project will require comprehensive testing and configuring before launch. If the implementation team fails to account for all the main variables present in the ERP project, the chances of delays increase.

This is what happened to the utility company National Grid. Worried about missing their already overdue rollout date, the organization had to launch their new ERP system in the midst of the aftermath caused by Superstorm Sandy.

The ERP failure touched multiple different business processes: employees were under- or overpaid, vendor invoices went unprocessed, and financial reporting flaked out. The company ended up filing a lawsuit against their SAP ERP vendor Wipro, settling for $75 million – unfortunately, the settlement wasn’t enough to cover for all the losses caused by the ERP failure.

Case study: Lidl

Main issue: Lack of organizational transparency, problems with data migration

ERP solutions should be tailored to each organization’s business processes. But when in-house legacy systems rely on logic that differs from the market standard, issues can arise.

This was the case with the supermarket chain Lidl and SAP (ERP system provider). As Lidl was keen on not changing the way it managed its inventory, the SAP implementation had to be heavily customized. After spending nearly €500 million on the ERP implementation, the project was eventually scrapped after 7 years.

On top of navigating the inventory logic of the legacy system, the project saw a high turnover in Lidl’s IT department leadership. This resulted in interorganizational problems with transparency and eventually the blame was shifted to the consultancy in charge of the SAP ERP system.

Case study: Mission Produce

Main issue: Insufficient understanding of system and business requirements

ERP projects fail for many reasons, but more often than not, ERP functionality isn’t fully understood until botched implementation.

This happened to the fresh produce brand Mission Produce. Despite spending hours and hours planning and preparing for the ERP rollout, the implementation was riddled with problems.

The system was meant to support international growth by providing the teams better visibility of their business operations and financial reporting. Unfortunately, the reality was far from this. The orgnaization lost track of their inventory, and had to rely on contractors while the problems were fixed, affecting the company’s profit margins.

The ERP failure was so severe that the business had to hire external consultants to fix the new ERP, costing the company nearly $4 million.

Case study: Hershey

Main issue: Rushed implementation and inadequate testing

ERP projects often fail due to insufficient preparation and overly aggressive timelines that prevent thorough testing and proper user training.

This happened to the confectionery giant Hershey’s in 1999. Hershey aimed to implement a new ERP system, along with supply chain management (SCM) and customer relationship management (CRM) software, within 30 months to meet a critical go-live date ahead of the Y2K deadline.

Despite the tight timeline, the company did not thoroughly test the system or adequately train its staff. As a result, when the system went live during the peak Halloween and Christmas seasons, it malfunctioned severely. Hershey couldn’t process $100 million worth of orders and experienced significant inventory management issues.

The failure led to a 19% drop in quarterly profits and an 8% fall in stock price. The company had to spend additional time and resources to stabilize the system and restore normal operations.

How to succeed in ERP implementation

Case study: K3 Business Technologies

One common reason ERP implementations fail is complexity, leading to low user adoption.

K3 Business Technologies faced this challenge when rolling out Microsoft Dynamics 365 Business Central. Without effective training, there was a risk of system underuse.

To overcome this, K3 utilized ClickLearn to create automated, easy-to-use training materials. This helped streamline the onboarding process, ensuring employees quickly adapted to the system.

As a result, K3 saw high user adoption, avoiding the pitfalls of ERP failure through effective user support and training.

Mitigation strategies for ERP implementation failures

- Comprehensive planning and scoping. Begin with a thorough needs assessment to align ERP capabilities with business objectives. Define clear milestones, roles, responsibilities, and success criteria. Ensure there is a dedicated project manager to oversee the process and maintain alignment among all departments.

- Strong change management and user engagement. Develop a change management plan that involves employees from the outset. Conduct workshops, feedback sessions, and regular updates to build a sense of ownership. Focus on training that is not just system-centric but also addresses how new processes will impact daily roles.

- Executive sponsorship and governance. Secure buy-in from senior leadership to ensure adequate resources and funding. Establish a governance framework with a steering committee to provide oversight, make timely decisions, and address escalations.

- Data preparation and migration. Cleanse and standardize data well before the implementation. Invest in data mapping tools and run migration tests to identify potential issues early. Ensure the data migration strategy aligns with the overall ERP project plan.

- Risk management and contingency planning. Identify potential risks (e.g., data loss, scope creep) and develop mitigation plans for each. Allocate a buffer in the timeline and budget for unforeseen challenges. Regularly review risks and adjust the strategy as needed.

- Iterative testing and quality assurance. Conduct multiple rounds of testing, including unit testing, integration testing, and user acceptance testing (UAT). Create a feedback loop to address issues promptly. Consider a pilot phase in a controlled environment to gauge performance and user response before a full rollout.

- Ongoing training and support. Offer continuous training programs tailored to different user groups to build competency and confidence in the new system. Provide accessible support channels such as help desks, user manuals, and e-learning modules to address ongoing queries.

- Post-implementation review and optimization. After the initial rollout, conduct a thorough post-implementation review to assess the project against key performance indicators (KPIs). Identify any gaps, areas for improvement, or additional user needs. Use these insights to optimize the ERP system further.

Free template

Download Software Rollout Plan

Implementing new software demands careful planning and coordination, but we’ve simplified the process for you. Download our ready-to-use template to help you organize your ERP implementation project and ensure successful onboarding and training for both your authors and end-users.

Avoid ERP implementation failure in your organization

Keep your own market credibility intact and avoid ERP implementation failure in your organization by conducting thorough research and testing practices from day one.

Realistically evaluate the system requirements that best support your organization’s daily operational processes. Ensure proper role-based end user training is carried out, and that all teams are on the same page when it comes to budget and time constraints.

Get proper return on investment and unlock new levels of growth with a well planned ERP implementation. Use a digital adoption platform like ClickLearn to get started.

Book a demo

Content is loading...

Why ERP implementations fail FAQ

ERP implementation failures can often be traced to several factors, including poor planning, lack of user adoption, inadequate training, and unclear business objectives. Other common issues include underestimating the complexity of the system and insufficient support from leadership.

- User adoption: Employees may resist the change if they are not adequately trained or if the system is too complex.

- Data migration issues: Transferring data from legacy systems to the new ERP can lead to errors and delays.

- Inadequate planning: Without a clear implementation strategy, timelines can be missed, and costs can spiral out of control.

Studies suggest that ERP failure rates can be as high as 50-75%, depending on the industry and the scope of the project. Failure can range from partial to complete, where systems are abandoned or underutilized.

ERP systems are challenging to implement due to their complexity and the wide range of functions they must support across an organization. They often require significant changes in processes, data management, and employee behavior, all of which can be difficult to align without careful planning and support.