What is Microsoft Dynamics 365 manufacturing ERP?

Microsoft Dynamics 365 is a collection of business applications mainly used for enterprise resource management (ERP) and customer relationship management (CRM). Being mainly cloud-based, Dynamics 365 applications help organizations track, analyze and view business data on various devices.

The software aims to improve operational efficiency and customer experience by aiding organizations to work in a more agile way, and identifying and reducing complex workflows without increasing costs. Dynamics 365 for manufacturing also helps to centrally manage product information and documentation, making training and change management an easier undertaking.

Why improve the digital adoption of D365 for manufacturing

The transition to digital platforms like Microsoft Dynamics 365 (D365) addresses various industry pain points, fostering a more efficient, agile, and competitive environment. With a digital adoption platform like ClickLearn, you can help streamline use adoption of D365 for manufacturing, and tackle some of the most common problems manufacturing companies struggle with.

Address production challenges

- Problem: Unplanned downtime due to equipment failure.

- Solution: Use Dynamics 365 for predictive maintenance through IoT integration, reducing unexpected stoppages.

One of the most critical issues in manufacturing is unexpected production downtime, which can lead to significant financial losses. Dynamics 365 helps mitigate this through advanced analytics and machine learning capabilities, enabling predictive maintenance. For example, by integrating IoT sensors with D365, manufacturers can monitor equipment health in real time, predicting failures before they occur. This not only reduces downtime but also extends the lifespan of machinery.

Combat employee turnover

- Problem: High turnover impacting operational continuity.

- Solution: Implement D365’s training modules for efficient onboarding and skill development.

The manufacturing sector often faces high employee turnover, which can disrupt operations. D365 addresses this by offering comprehensive training modules within its platform, facilitating quicker onboarding and continuous skill development. The platform’s intuitive design and personalized learning paths reduce the learning curve, making it easier for new employees to adapt and for existing employees to upgrade their skills.

Customization and flexibility

- Problem: Unique manufacturing processes require tailored solutions.

- Solution: Customize Dynamics 365 to fit specific operational needs, improving workflow and productivity.

Manufacturers frequently encounter the need for customized solutions due to unique processes and products. Dynamics 365’s modular nature allows for tailored configurations that fit specific business needs, enhancing operational efficiency. For instance, a manufacturer can customize the D365 interface to streamline workflow, ensuring that employees have quick access to necessary tools and information, which in turn can lead to improved productivity and reduced training time.

Supply chain optimization

- Problem: Disruptions leading to operational delays.

- Solution: Utilize D365 for real-time supply chain visibility and predictive insights to mitigate risks.

Supply chain disruptions can severely impact manufacturing operations. Dynamics 365 offers comprehensive supply chain management tools that provide real-time visibility and predictive insights. This enables manufacturers to anticipate supply chain disruptions and adjust plans accordingly, ensuring that production continues smoothly. Additionally, D365 can automate inventory management, reducing the likelihood of stockouts or excess inventory.

Overcome resistance to change

- Problem: Employees resistant to new technology.

- Solution: Leverage user-friendly interfaces and personalized learning with D365 to facilitate adoption.

Resistance to new technologies can hinder digital adoption. Dynamics 365 helps overcome this through user-friendly interfaces and interactive learning tools. By involving employees in the digital transformation process and providing clear benefits, such as reduced manual tasks and easier access to information, organizations can foster a more accepting culture.

Promot paperless manufacturing

- Problem: Excessive use of paper on the shop floor.

- Solution: Adopt D365 mobile capabilities for real-time access and updates, moving towards a paperless environment.

The move towards paperless manufacturing is facilitated by D365’s mobile capabilities, allowing staff to access information and perform tasks using tablets or smartphones directly on the shop floor. This not only reduces paper waste but also increases efficiency and accuracy, as updates and data entry can be done in real time.

Enhance quality management

- Problem: Maintaining high product quality standards.

- Solution: Integrate automated testing and quality checks with D365 to ensure product integrity.

Quality management is crucial in manufacturing. Dynamics 365 supports automated process testing and quality checks, ensuring that products meet stringent standards. By integrating quality control measures directly into the production process, manufacturers can reduce defects, decrease rework, and enhance customer satisfaction.

Maximizing the potential of D365 for manufacturing through effective software training

Training is pivotal in harnessing the full potential of Dynamics 365 within the manufacturing sector. Effective training with a digital adoption solution like CilckLearn ensures smoother transitions, better user engagement, and maximized software utility.

Some of the major benefits of effective user adoption of D365 for manufacturing include the following:

1. Comprehensive understanding and ability to use the new software

- Why: Reduces errors and improves operational efficiency.

- Example: Employees trained in D365 can navigate the system efficiently, minimizing input errors and streamlining processes.

- Do this: Develop role-specific training modules for targeted learning.

Effective D365 training ensures employees use the system correctly, reducing operational errors. With clear instructions and hands-on exercises, staff can perform tasks more efficiently, leading to smoother workflows and increased productivity.

2. Enhanced problem-solving skills for end users

- Why: Employees can troubleshoot issues independently.

- Example: A trained worker identifies a software glitch affecting production and resolves it using D365’s support features.

- Do this: Incorporate practical problem-solving exercises into training sessions.

Training empowers employees to troubleshoot independently, minimizing downtime. By understanding D365’s features, they can quickly resolve issues, maintaining continuous production and service quality.

3. Improved data-driven decision making

- Why: Better insights lead to informed decisions.

- Example: Staff use D365 analytics to optimize production schedules based on real-time data.

- Do this: Train employees on interpreting D365 analytics and reports.

Well-trained employees can leverage D365’s analytics for strategic decisions, optimizing resources and forecasting trends, which leads to better planning and competitive advantage.

4. Streamlined and more effective onboarding process

- Why: Quicker adaptation for new employees.

- Example: New hires use D365 training tools to understand their roles faster, reducing the time to become productive.

- Do this: Create an onboarding training plan incorporating D365 tutorials.

Structured D365 training accelerates new hire acclimation, reducing the time to productivity and enhancing their initial experience.

5. Higher employee retention and satisfaction

- Why: A well-trained workforce feels more competent and valued.

- Example: Employees who understand how to use D365 effectively are less likely to leave due to frustration or lack of engagement.

- Do this: Regularly update training materials and gather feedback for improvements.

Comprehensive training leads to higher job satisfaction and retention rates. Employees who feel competent and skilled are more engaged and less likely to seek opportunities elsewhere.

Best Microsoft Dynamics 365 apps for manufacturing

As Microsoft products go, there are many solutions and new technologies to choose from depending on customer demand, business models, and more. We recommend considering at least the following Dynamics 365 apps for manufacturing.

Dynamics 365 Business Central

Most small and medium-sized manufacturing businesses are able to benefit from this app.

Being all about working smarter, not harder, this Dynamics 365 app is the perfect all-rounder enterprise resource planning (ERP) system. The app uses business intelligence and machine learning to improve production flows, reduce errors and improve margins, helping manufacturers stay one step ahead of market trends.

Dynamics 365 also supports all the other Microsoft tools, from Power Apps to Office 365. Thanks to MicrosoftAppSource, you can add specific functionality to your ERP by installing third-party extensions, making it easy to tailor Dynamics 365 to suit your market and niche.

If you’re looking for a highly scalable tool to support your manufacturing operations, we recommend Dynamics 365 Business Central.

This Dynamics 365 application makes managing business finances seamless and intuitive.

On top of the general financial management and accounting functionality, Dynamics 365 Finance uses artificial intelligence to help predict clients’ financial behaviour, natively handle the current exchange, create smart budget proposals based on historical data, and much more.

Instead of spending hours adapting documents to suit different legal and business requirements, you can unify reporting with Microsoft 365 templates. Various ready-to-use matrixes, configurations, and dashboards make it easy to get a birds-eye view of different tax scenarios, invoice delivery, and local compliance.

This app helps you unify financial business processes and make data-driven decisions while scaling your business.

The Microsoft Dynamics 365 Supply Chain Management app is a must-have for the manufacturing sector.

Probably one of the most comprehensive solutions on the market, Dynamics 365 makes supply chain and inventory management effortless. From agile planning and procurement to using cloud computing to manage and automate shop-floor processes, this app enables your team to respond quickly to any issue.

Run a smart factory and make decisions based on real-time data with Dynamics 365 Supply Chain Management.

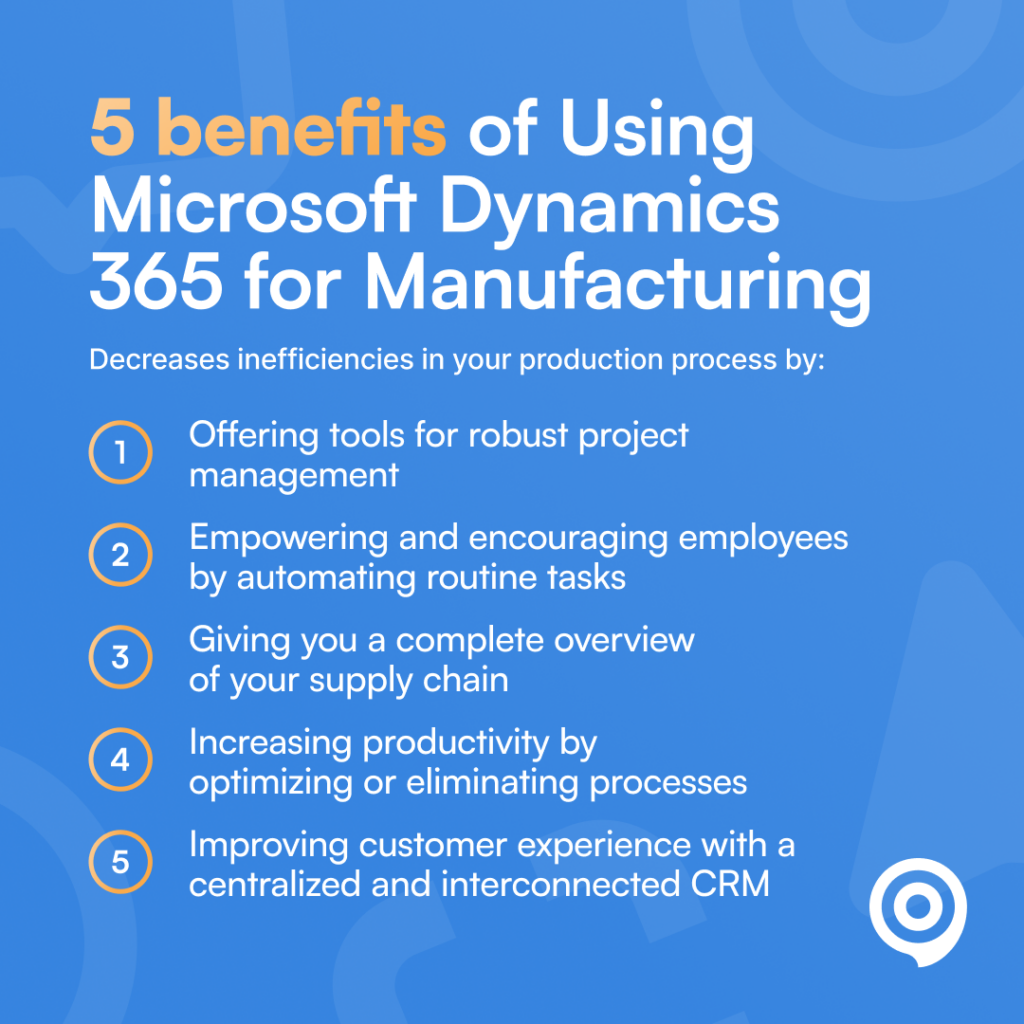

5 benefits of using Microsoft Dynamics 365 for a manufacturing business

Looking for a solution to bring together all of your key business metrics, from supply chain management to sales, customer service, and more? Dynamics 365 for manufacturing and distribution helps you gain visibility to your production process by:

- Offering tools for robust project management

- Empowering and encouraging employees by automating routine tasks

- Giving you a complete overview of your supply chain

- Increasing productivity by eliminating and optimizing processes

- Improving customer experience with a centralized and interconnected CRM

1. Robust project management

Unfortunately, project cost and schedule overruns are commonplace for most organizations. When teams are unable to collect, analyze and visualize important metrics, like estimated costs and predicted revenue, it’s hard to reach the initial project goals in the first place.

Especially for manufacturing businesses, understanding production capacity, quality and cost help to optimize workflow efficiency and operations overall. With Dynamics 365, you can monitor the entire manufacturing process through easy-to-use dashboards and quickly make data-driven decisions.

Thanks to AI-driven forecasting, you can take action before there are any critical changes to your KPIs, ensuring maximum operational efficiency and profitability. Dynamics 365 also makes it effortless to follow resource allocation in real-time, automating asset management and utilization. With proper operational visibility, you can get the most out of your business operations and avoid scheduling conflicts or unnecessary downtime.

2. Empowering employees

Successful digital transformation is all about proper end-user training set in contextual learning environments. With tools like Microsoft Dynamics 365, you can streamline many manufacturing processes and automate many core processes, freeing your employees’ time for more important tasks.

But all tools are just as good as the people using them. Often, software and ERP implementations fail due to a poor or complete lack of role-based training. Luckily, Dynamics 365 has a robust and comprehensive user access management system, making it easy to access role-specific tools, training modules, and dashboards.

By offering employees access to comprehensive tools like Dunamics 365, repetitive and mundane tasks can be automated, resulting in an increase in overall employee satisfaction.

3. Complete overview of the supply chain

Supply chains have a tendency of getting complex and hard to manage after manufacturing organizations reach a certain size. It can be tough to manage all the data from suppliers, manufacturing operations, sales, customer service, and order fulfilment and shipment teams.

Microsoft Cloud for manufacturing addresses supply chain management issues comprehensively. The system combines data from all the different sources and uses AI-driven algorithms and machine learning to monitor the complete supply chain. It helps you better understand your current processes, adapt to changing market trends or sudden developments, and identify areas for improved production efficiency.

Centralizing your supply chain operations makes it easier to create accurate budgets, delivery schedules and forecasts and improve operational efficiency overall. And since Dynamics 365 is cloud-based, the production process can be monitored from mobile devices, making all supply chain data easily accessible regardless of geographical location.

4. Increased productivity

With Dynamics 365, your team can focus on bigger-picture tasks, rather than spending time on repetitive processes. Thanks to the cloud-based integrated dashboards, you can view all the key business data and maximize your asset usage remotely, on various devices.

From customer service to sales, Dynamics 365 easily integrates with Office 365, making document creation, event-centric sales processes, workload prioritization, and remote work efficient and commonplace. Since everything is recorded in a single system, teams are more aligned overall, and time spent on redundant meetings is reduced.

The financial and production forecasts help technicians fine-tune production to meet demand while keeping costs down. Easily filtered and displayed data also makes it easier to understand how different production assets, like manufacturing plants or other high-value equipment, are being utilized, making it easier to optimize production further.

5. Improve customer relationships

By being able to offer more personalized service to your clients, you are able to increase customer engagement and overall satisfaction. Dynamics 365 enhances business continuity by enabling different teams to access and update customer data in one place.

Sales teams can view historical data and understand client needs better and tailor future orders to better reflect client needs. Similarly, service technicians can easier support clients by having a complete overview of the client. Dynamics 365 helps you provide high-quality, resolution-focused self-service support thanks to knowledge documentation tools, freeing and focusing the support team’s time on more complex tasks.

McKinsey also found a clear correlation in potential revenue increases after manufacturing businesses applied insights from the customer journey to their customer experiences.

Achieve digital transformation with Microsoft Dynamics

Staying on top of the ever-evolving technological advances in the manufacturing business can be challenging. Companies are required to act fast and be on top of the market trends to remain competitive.

Thankfully, tools like Dynamics 365 empower decision makers and employees alike to make informed, data-driven decisions. Enhance innovation and improve the operational efficiency of your manufacturing company today.

Staying on top of the ever-evolving technological advances in the manufacturing business can be challenging. Companies are required to act fast and be on top of the market trends to remain competitive.

Thankfully, tools like Dynamics 365 empower decision makers and employees alike to make informed, data-driven decisions. Enhance innovation and improve the operational efficiency of your manufacturing company today.